水泥电杆在运输和施工中开裂的原因,主要因为水泥电线杆强度不够,质量过差导致水泥电线杆开裂,在运输中出现压碎和顺向开裂都是因为生产水泥电线杆采用了劣质的原材料导致。在对水泥电线杆施工过程中经常出现开裂和破损现象,很多种原因导致水泥电线杆破损,主要原因还是质量不合格导致水泥电线杆破损,在生产水泥电线杆时为了节省成本减少水泥和钢筋导致强度过低导致破碎。

The main reasons for the cracking of cement pole in transportation and construction are that the strength of cement pole is not enough and the quality of cement pole is too poor, which leads to the cracking of cement pole. Crushing and forward cracking in transportation are caused by the poor raw materials used in the production of cement pole. Cracking and breakage often occur during the construction of cement wire rod. Many reasons lead to the breakage of cement wire rod. The main reason is that the quality of cement wire rod is not up to standard. In order to save cost and reduce the strength of cement and steel bar, too low leads to breakage.

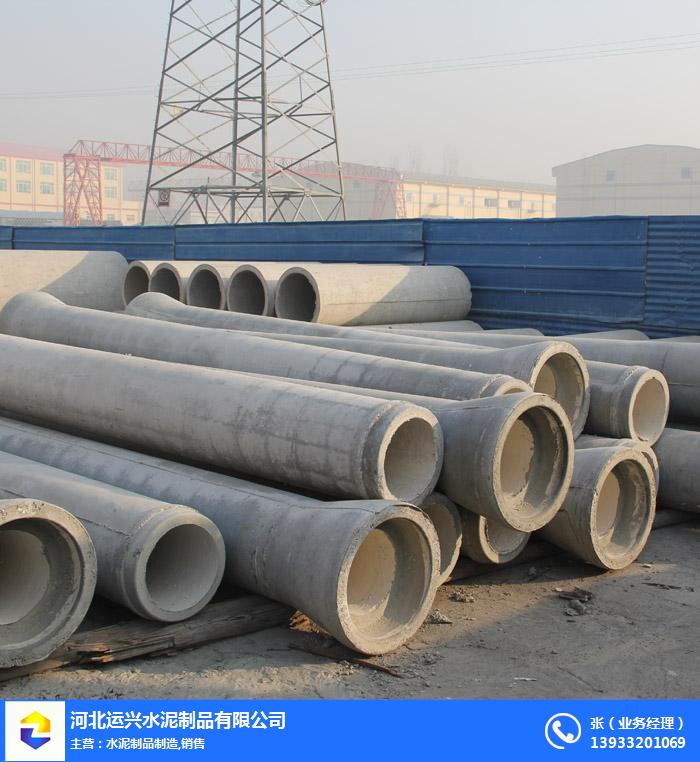

影响水泥电杆破损原因

Reasons for Damage of Cement Pole

一,水泥使用量少,降低混凝土的强度导致水泥电线杆破碎。

First, the use of cement is small, reducing the strength of concrete leads to the breakage of cement wire pole.

二,减少外环筋,导致水泥电线杆顺向开裂。

Second, reduce the external ring reinforcement, leading to the cement pole cracking in the direction.

三,主筋减少使用量容易导致水泥电线杆纵向断裂。

Thirdly, the reduction of main reinforcement tendons can easily lead to the longitudinal fracture of cement poles.

四,采用劣质的砂石料,人工沙和较差的石子,不达标的水泥都会导致水泥电线杆开裂。

Fourth, the use of inferior sand and gravel, artificial sand and poor stone, not up to the standard cement will lead to cement pole cracking.